Find the pages, products, documents, and resources with a full site search.

Advanced Document SearchIntegrity for Life

If pipes are your business, Sponge-Jet can take care of your concerns. From preparing the inside of a pipe with total confidence of perfect results time after time – to assuring successful inspections – to cleaning and profiling weld seams. Sponge-Jet has your pipes properly covered. The ability to dry-commission complete units and perform dust-free open blasting it now possible without compromising surface cleanliness and consistent profile. Sponge Media™ is a dry, low dust, reusable process. Its characteristics increase the reliability and integrity of your assets.

Features & Benefits

- Simplify job staging

- Protect integrity & reliability of equipment

- Blast on operating equipment

- Increase asset life & coating performance

- Extend time between repairs

- Increase production and profits

Rotary Spin Blasting with Sponge Media

Sponge Media™ abrasives provide many advantages when blasting inside pipes and tubes. Field contractors, pipe manufacturers, and facility owners are now using Sponge-Jet media inside pipes to provide quality, cost-effective cleaning and surface preparation.

Protecting the Italy's Po River

When installing this new pipeline near a local river there were concerns over the use of ordinary abrasives and their impact on the environment. All weld seams needed to be blasted after the weld joints were made. The contractor selected Sponge-Jet as the most cost effective and non-invasive method (allowing simplified containment), which also addressed concerns voiced by the local community and authorities.

Insitu Pipe Joint Preparation

PETROBRAS. the national oil company of Brazil, uses Sponge-Jet to prepare weld areas prior to receiving a specialized coating system for joints. Formerly, onsite preparation was challenging due to restrictions around ordinary abrasive blasting. Now contractors blast with Sponge-Jet, achieving perfect preparation and long-term coating results.

New Pipeline Construction Sponge Blasting

This Puerto Rican pharmaceutical plant located near residential housing and a sensitive ecosystem was constructing a new waste-water pipeline that required abrasive blasted on site. In Puerto Rico blasting with ordinary abrasives is highly regulated, Open-air abrasive blasting is prohibited only with government approval and a special permit - however Sponge-Jet has been granted exception and may be used freely for open-air blasting.

Preparing Pipelines for Argentina’s largest Oil Company

Argentina’s largest oil and gas producer used Sponge-Jet Silver 30 Media™ abrasives to blast live, under pressure process pipes to a White Metal Cleanliness (SA3 (SSPC-SP5 / NACE 1) with a 100 micron (4 mil) profile. Performing the work during normal operations allowed the plant to upgrade to a superior maintenance coating system while lowering total cost and reducing critical-path work on shutdowns.

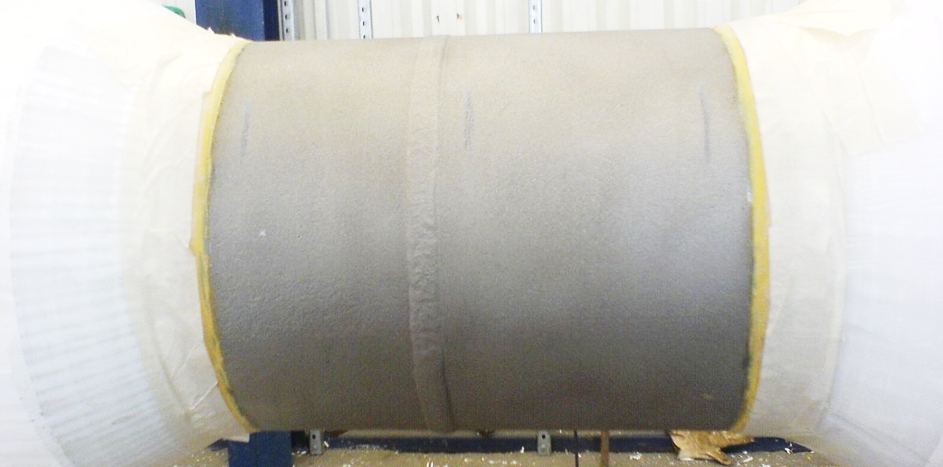

Pipe Manufacture uses Composite Abrasive

This world-leading pipe manufacture uses Sponge-Jet technology - two fixed-position B-VAC Pro™s to blast pipe internals on an automated machine. The advantage of improved quality, reduced dust and disruption in the manufacturing plant all led to the decision to standardize their process and use Silver 30 Sponge Media™ abrasives.

Process Pipelines Prepared

This petrochemical plant needed to recoat the exterior of it’s process pipes. Ordinary blasting technology would have required extensive containment to reduce damage to the nearby equipment. Sponge-Jet was used to obtain a near-white metal blast with minimal staging and no disruption to other trades.

Robotic Pipe Blasting with Sponge-Jet

Their own research group has determined that, compared to other methods, Sponge Blasting improves adhesion to concrete surfaces by 50% more than when using ordinary abrasives.

Centro Risorse Sponge-Jet

Risorse

Centro Risorse Sponge-Jet

Risorse

868 Repairing Injection Water Pipes in Cooling Tower of Sugar Mill

Case history detailing repairs to injection water pipes in sugar mill where Sponge-Jet was used; ex…

Scarica

Sponge-Jet Use in Concrete Pipeline in Power Plant

PDF article describes Sponge-Jet used with robotic blast cart to remove failed coating on undergroun…

Scarica

Blog

Recent Blog Posts

Power Tooling vs Abrasive Blasting for Surface Prep

Power tooling is a method of surface preparation commonly used in tight spaces where access is limited. Pneumatic, electric, and hand tools such as angle grinders, needle guns, wire wheels, wire brushes, scrapers, and sanding pads can be used to remove rust, paint, and other contaminants from a surface.

Per saperne di più >

Sponge Media and the Marine Industry

Both Freshwater and Saltwater vessels see all sorts of contaminants and corrosion throughout their service life. Corrosion can threaten everything on ships, from power gen and water storage tanks, to their general structural integrity. In order to overcome these threats, proper surface preparation is key.

Per saperne di più >