Protecting Workers From The Hazards of Abrasive Blasting Materials

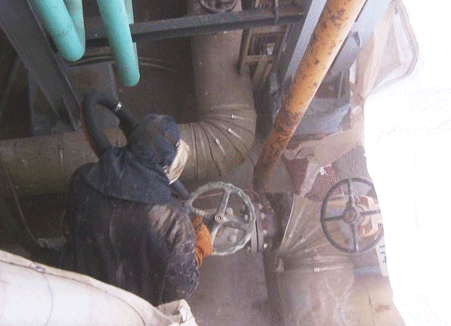

Worker health and plant safety issues are dramatically improved when Sponge-Jet technology is used for surface preparation. Fugitive emissions (TSP and PM-10) can be reduced as much as 97% over traditional abrasive blasting, drastically reducing reportable environmental emissions. Sponge Media particles capture the contaminants removed from the surface – reducing worker exposure to hazardous airborne dust normally caused during abrasive blasting. Injuries caused by abrasive ricochet are eliminated. Sponge Media is also recycled which can reduce waste disposal up to 96%.

The industry term “low dust blasting” is commonly being replaced by “dustless blasting.” Review the US Environmental Protection Agency for complete test results on abrasive emission factors in file AP-42 and its independent companion update “Emission Factor Documentation for AP-42 Section 13.2.6”

Testimonials

"We recommend Sponge-Jet as an environmental friendly abrasive blasting method which fulfills our health and environmental regulatory requirement.” - Mechanical Manager, TownGas

Risorse addizionali

MRI – Emission Study

PDF document details laboratory test results that blast operations utilizing Sponge-Jet sponge-encap…

Scarica

Sponge-Jet Introductory Brochure – ITA

Tecnologia di sabbiatura abrasiva

Scarica

a bassa emissione di polvere

Proteggere ciò

che è importante

n L…

California Air Resources Board Certification-CARB

PDF approval letter by California Air Resources Board (CARB) announcing certification that Sponge-Je…

Scarica

Lead Suppression Tests

PDF 3rd party report discusses results of Maine Department of Transportation airborne lead testing a…

Scarica

Recent Blog Posts

Power Tooling vs Abrasive Blasting for Surface Prep

Power tooling is a method of surface preparation commonly used in tight spaces where access is limited. Pneumatic, electric, and hand tools such as angle grinders, needle guns, wire wheels, wire brushes, scrapers, and sanding pads can be used to remove rust, paint, and other contaminants from a surface.

Per saperne di più >

Sponge Media and the Marine Industry

Both Freshwater and Saltwater vessels see all sorts of contaminants and corrosion throughout their service life. Corrosion can threaten everything on ships, from power gen and water storage tanks, to their general structural integrity. In order to overcome these threats, proper surface preparation is key.

Per saperne di più >