Find the pages, products, documents, and resources with a full site search.

Advanced Document SearchAvoid Premature Equipment Failure

Fine atomized abrasives are the enemy of machinery and equipment as well as those responsible for keeping them operating. Micron-sized abrasive particles travel freely throughout a plant and can penetrate deep into every component, damaging shafts, cylinders, electronics, switches, sensors, bearings, mechanical seals and all rotating or moving parts. Thermal, electrical and corrosive properties of abrasives can also take a toll on electronics.

Uncontained dust from abrasive blasting can destroy valuable machinery like:

- Turbines

- Compressors

- Actuated valves

- Ventilators

- Motors & engines

- Pump

Sponge-Jet’s MicroContainment™ technology allows for abrasive blasting directly adjacent to sensitive equipment – with an 98% reduction in dust; it also nearly eliminates the damaging ricochet commonly associated with ordinary abrasives.

Features & Benefits

- Simplify job staging

- Blast on operating equipment

- Extend time between repairs

- Increase production and profits

- Protect integrity and reliability of equipment

- Increase asset life and coating performance

Pressurized Lines in Fuel Plant

This liquid gas plant in Argentina blasts with Sponge-Jet on live, pressurized lines during plant operations. This change in process allows maintenance painting to occur continuously without waiting for shut down. By eliminating these critical path interruptions during shut downs their schedule is greatly simplified and shut downs are shortened, increasing production and saving money.

Compressor Overhaul at Refinery

Interior and Exterior compressor overhaul at a Pemex Refinery in Mexico. The challenge was to remove oil residue, corrosion and profile for recoating on the exterior and to remove all oil residue and seal adhesive without substrate damage on the interior.

Cleaning Process Chemical Spills

Process chemicals, grease and oil (and other) spills can be easily removed with the dry process using the Blue and Green Sponge Media™ products. By avoiding the use of liquids (e.g. water, steam, solvents and harsh chemicals) the risks of contaminating the plant's waste water system are nonexistent. Dry-cleaning with Sponge Media avoids corrosion, mold and keeps workers at a safe distance, avoiding direct contact or splash exposure.

Kitchen and Food Processing Equipment

In this food plant, the support frame under the newly installed oven needed to be cleaned and prepared. By using the dry, low ricochet technology of Sponge Blasting, the facility was able to complete the project quickly with no damage or contamination to surrounding equipment.

Corrosion Protection of Structural Steel

Structural steel, machinery frames (supports) and conveyors all suffer from corrosion in most industries. This USA steel manufacturer found Sponge-Jet blasting the ideal solution to achieve excellent surface preparation without damaging the nearby equipment or the thousands of conveyor bearings and seals.

Stripping Mold Release Agents and Flashing

Clean and rejuvenate industrial molds used in the manufacturing of tires, instrument panels, formed body panels and other large components. The delicate, surgical like control the Sponge-Jet Feed Units™ combined with the gentle cleaning power of sensitive Sponge Media™ products provide a precise and efficient tool to protect costly industrial molds.

Surface Preparation on Process Equipment

Pumps, valves and other process piping components are being prepared (while operating) at this Repsol fuel distribution plant. Normally dust and fugitive emissions would penetrate mechanical seals, bearings and other rotating items – causing future reliability issues. Not with Sponge-Jet... the plant maintains quality coatings systems without compromise or fear of damaging sensitive equipment.

Coating Repair on New Machinery

The delicate, precise control of Sponge Blasting allows contractors, owners and OEMs to repair or recoat machinery while maintaining like-new integrity of the sealed rotating components. This low ricochet and low dust technology allows for high-quality surface preparation without damage to adjacent bearings and seals.

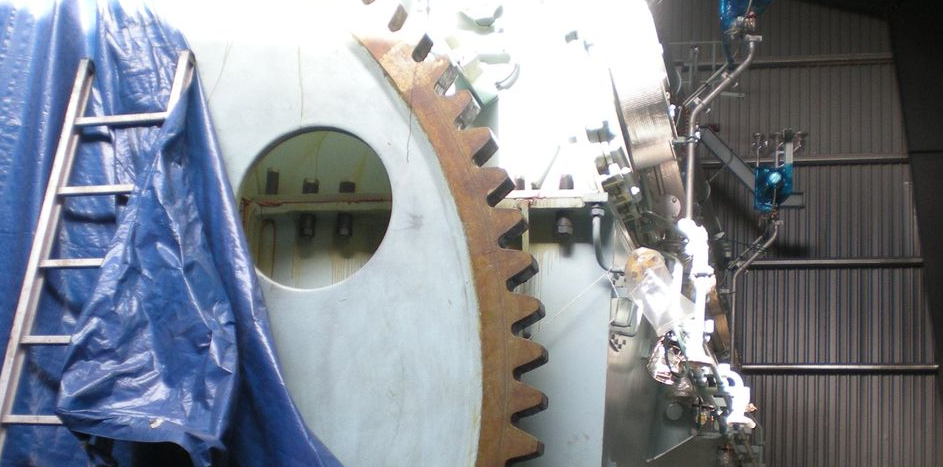

Engines, Compressors, Transmissions

Large mechanical equipment is subject to degradation from dust and ricochet from nearby abrasive blasting. Sponge-jet composite media virtually eliminates these issues and allows efficient, high quality coating maintenance on and adjacent to valuable machinery and equipment.

Sponge-Jet Resource Center

Ressurser

Blogg

Recent Blog Posts

Power Tooling vs Abrasive Blasting for Surface Prep

Power tooling is a method of surface preparation commonly used in tight spaces where access is limited. Pneumatic, electric, and hand tools such as angle grinders, needle guns, wire wheels, wire brushes, scrapers, and sanding pads can be used to remove rust, paint, and other contaminants from a surface.

Read More >

Sponge Media and the Marine Industry

Both Freshwater and Saltwater vessels see all sorts of contaminants and corrosion throughout their service life. Corrosion can threaten everything on ships, from power gen and water storage tanks, to their general structural integrity. In order to overcome these threats, proper surface preparation is key.

Read More >