Earn Higher Margins By Providing Better Value and Total Cost Solutions To Your Clients

Avoid disruptions to client operations, drastically reduce risk of damage to their valuable equipment, provide them superior coating life and extend time between maintenance projects. Sponge Blasting technology allows contractors to provide more total value to their clients; it allows contractors to differentiate themselves and become an invaluable part of their customer’s team.

Testimonials

"Navantia... will continue counting on the Sponge-Jet technology for surface preparation and we congratulate you for the quality of your products and the service you provide us." - Pedro Pedraza Bergillos, Program Manager, Navantia

Related Resources

Chloride Removal Paper

PDF white paper compares dry abrasive blasting with pliant abrasive blasting, focusing on chloride r…

Download

Chloride Removal Test

PDF letter describes how Sponge-Jet abrasive blasting lowered chloride levels below 10 mg/cm² in on…

Download

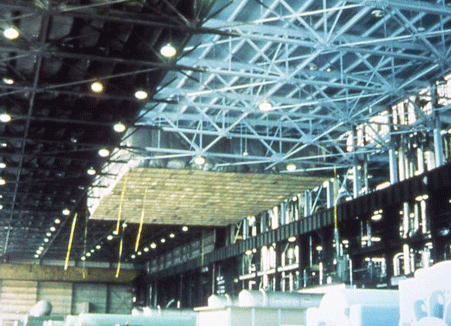

Paint Removal in Manufacturing Plant

PDF describes case history of Sponge-Jet low dust coatings removal inside robotics plant containing …

Download

Sponge-Based Technology Can Cut Cleaning Downtime

PDF article describes abrasive-blast airborne dust problem encountered at manufacturing facilities.

Download

Recent Blog Posts

Power Tooling vs Abrasive Blasting for Surface Prep

Power tooling is a method of surface preparation commonly used in tight spaces where access is limited. Pneumatic, electric, and hand tools such as angle grinders, needle guns, wire wheels, wire brushes, scrapers, and sanding pads can be used to remove rust, paint, and other contaminants from a surface.

Läs mer >

Sponge Media and the Marine Industry

Both Freshwater and Saltwater vessels see all sorts of contaminants and corrosion throughout their service life. Corrosion can threaten everything on ships, from power gen and water storage tanks, to their general structural integrity. In order to overcome these threats, proper surface preparation is key.

Läs mer >