Reduce Variables And Liabilities

Increase asset life and the time between shutdowns. Alleviate community concerns and optimize strategic asset management. Sponge-Jet technology replaces disruptive surface preparation practices, reducing up to 30% of shut-down time – while increasing coating life. Ultimately one can extend both operational status and maintain asset value. Non-invasive Sponge Blasting technology allows:

- Most preparation and coating work to be achieved during regular operations (leaving shutdowns free for other trades)

- Management to improve, predict and control their operational schedules

- Management to eliminate community environmental concerns by reducing hazardous fugitive emissions

Testimonials

"In regards to the new technology, our experience has being satisfactory from the technical stand point regarding the operators safety and the impact to the environment. The equipment is reliable and the substrate finish quality is excellent." - Ronmel García, Maintenance & Programing Superintendent, Petrosucre-PDVSA

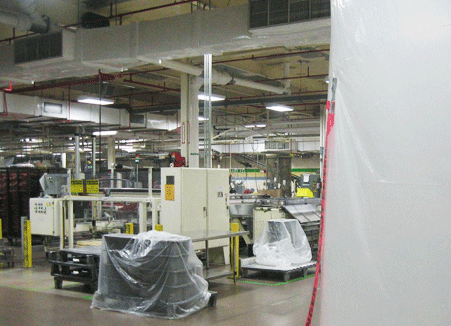

"This system is ideal for use with motors since it reduces dust and particulate normally generated during surface preparation. This significantly reduces the risk of contaminating the motor." - Wally Elger, Noesis, Inc.

“Composite media abrasives helped in saving us time and money that would have gone to a shipyard.” - Ken Peterson, Marine Superintendent, Sandy Hook Pilots

"We recommend Sponge-Jet as an environmental friendly abrasive blasting method which fulfills our health and environmental regulatory requirement.” - Mechanical Manager, TownGas

Related Resources

Being Green Good Article

PDF article describes Sponge-Jet’s greener approach to preserving structural assets and boosting p…

Download

Hazards of Conventional Abrasives

PDF magazine article describes health hazards associated with conventional abrasives, including sand…

Download

SJ Saves Water in Refinery

PDF article shows how switching from chemical cleaners to Sponge-Jet at Brazilian refinery helped de…

Download

Sponge-Jet Introductory Brochure

PDF document shows how Sponge-Jet’s abrasive blasting technology protects worker health and the en…

Download

Recent Blog Posts

4 Reasons Why You Should Care About Surface Prep

Painting a surface might seem like a straightforward task, but the key to a long-lasting and visually appealing finish lies in surface preparation. Whether you're dealing with metal or concrete, investing time and effort in preparing the surface before applying paint is essential.

Read More >

Traditional Sponge Media vs Sponge Media DG

Sponge-Jet boasts a wide range of composite abrasives used in a variety of industries and applications. Sponge Blasting is a dry process that typically falls under the abrasive blasting category. While many are familiar with our standard types of Sponge Media™, Sponge-Jet also offers some Sponge Media types with a designation of "DG" - within this article, we'll discuss what this means.

Read More >