Find the pages, products, documents, and resources with a full site search.

Advanced Document SearchReduce Downtime and Improve Operating Efficiency

Frequency and duration of corrosion mitigation or prevention projects affect the bottom line. Follow the success of power plants around the world using Sponge-Jet composite abrasives throughout the facility:

- Boiler, condensers and water boxes

- Heat recovery units

- Boiler stacks and chimney’s

- Turbines

- Refrigeration & cooling water lines

- Confined spaces

- Pumps, valves and gates

- Penstock

- Nuclear and other hazardous materials decontamination

Achieve the superior surface preparation required by high-performance coatings to enable maximum adhesion and life-expectancy. Increase profits by extending coating life.

Features & Benefits

- Improve heat recovery and transfer efficiency

- Turbine production efficiency

- Protect integrity & reliability of equipment

- Blasting on operating equipment

- Improve community relations & compliance

- Increased asset life & coating performance

Swift, In-service Coating Repair; Only Possible with Sponge-Jet

A coating change to already delivered wind turbines required swift action to remove/reapply a new system before installation; Sponge-Jet, the only option, on the internals of the steel tower, employed Silver 30 Sponge Media™ abrasive which created an Sa3 (NACE 1 / SSPC SP-5) White Metal Blast cleanliness level and 65micron (2.5mil) profile.

Remote Access Blasting Next to Live, High-voltage Sub-station Wires

Sponge Blasting navigates live high-voltage wires, multiple transformers and ground structures, strong coastal winds to blast corroded zinc-coated steel structure of a Chilean sub-station,. Images show the ease of containment and media collection – for reuse.

Sponge-Jet Removes it All in Power Plant - Soot, Creosote and Lead-Paint

What started as a fire restoration project turned into a major coatings overhaul and in process a lead paint abatement project at Port Jefferson Power Plant (New York); the lead dust-suppressing characteristics of Sponge-Jet helped extend this soot/creosote removal project to lead-paint abatement on walls, furnace, stairs and columns.

Alstom - No Transport Cost and Liability During Turbine Part Maintenance

Alstom energy company management (Spain), formerly against using abrasive blasting to clean its turbine parts, quickly switched from manual wiping with Scotch-Brite™ to mechanical blasting with Silver 320 Sponge Media™ abrasives when it learned blasting took place just meters from the base and saw the consistency and quality of the cleaned surface.

Sponge-Jet Sweeping Nation as Preferred Ethanol Plant Cleaning Method

The dry, low dust creosote-cleaning benefits of Sponge-Jet are sweeping through ethanol plants as facilities try to reduce maintenance downtime; whether it’s this regenerative thermal oxidizer or motors, dryers, dampers or air-to-air preheaters, Sponge-Jet micro-abrasive cleaning is much more efficient than any wet solution do to the simplicity of job staging and clean-up and the enhanced visibility during cleaning – which collectively accelerates total job duration.

Super-high Quality Cleaning of Wind Turbine Nacelle

Coating repair on this wind turbine nacelle prior to assembly in a mid-west (US) wind farm. Note near perfect visibility and low media rebound, allowing for a more productive environment - promotes clean consistent White Metal Blast Cleaning levels.

Sponge-Jet Surface Preparation Improves Motor Life and Efficiency

The cleaning of accumulated grease and soot from critical motors like this 1,000hp FD fan motor in an ethanol plant extends its working life and efficiency; the contractor, during a timed shutdown, Sponge Blasted this one in situ and with pressure to complete the project prior to the line starting back up.

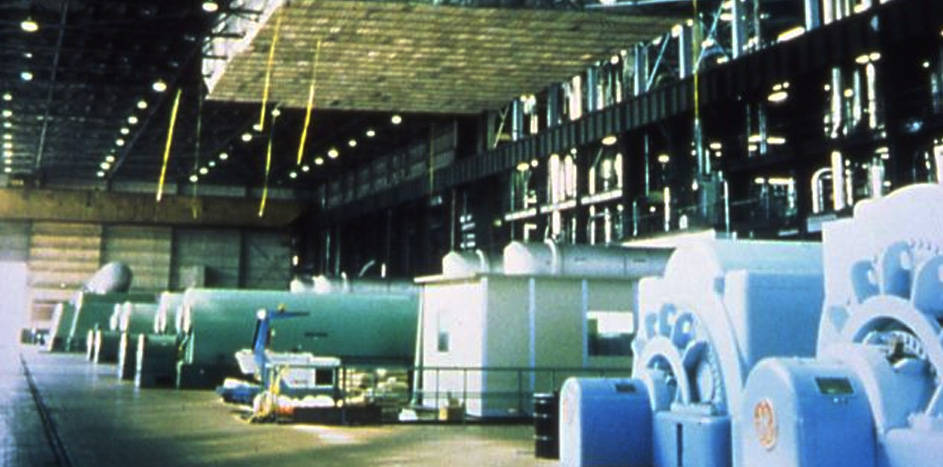

Power Plant Continues Productivity; Uses Sponge-Jet for Cleaning After Fire

Sponge-Jet was used at coal-fired plant, Alabama Power just after a turbine fire contaminated the plant’s ceilings. While emergency replacement turbines sit below, a dry, dust-controlling cleaning method became critical. Sponge-Jet met the challenge and actually profiled ceiling substrates so they could also be repainted.

Sponge-Jet and Pig Save Refinery Millions in Liters and Dollars

Sponge-Jet and a pipe pig are used to dry clean refinery process pipe interiors in the world’s first sustainable commissioning; the process is saving millions of liters of water and millions of dollars by reducing water transportation, processing and treatment requirements.

Sponge-Jet 资源中心

Resources

Sponge-Jet 资源中心

Resources

400-HP Feed Unit Manual CE – CHI

©2007 Sponge-Jet, Inc.

Download

35-P 50-P Recycler™ Manual CE – CHI

Sponge-Jet®海绵喷砂系统

Download

介质回收器

用户手册

型号:

35-P

50-P

Sponge-Jet, Inc.

Xtreme Riding Team – CHI

Lock and RollTM

Download

紧固系统:

– 定制设计的锁紧系统将两个设备连接

起来,�…

MicroContainment Diagram – CHI

磨料喷砂技术比较

Download

传统的磨料混合在 Sponge Media 里 TM

传统磨料喷砂材料

单�…

博客

Recent Blog Posts

Power Tooling vs Abrasive Blasting for Surface Prep

Power tooling is a method of surface preparation commonly used in tight spaces where access is limited. Pneumatic, electric, and hand tools such as angle grinders, needle guns, wire wheels, wire brushes, scrapers, and sanding pads can be used to remove rust, paint, and other contaminants from a surface.

Read More >

Sponge Media and the Marine Industry

Both Freshwater and Saltwater vessels see all sorts of contaminants and corrosion throughout their service life. Corrosion can threaten everything on ships, from power gen and water storage tanks, to their general structural integrity. In order to overcome these threats, proper surface preparation is key.

Read More >